Hernon® offers custom designed and/or off-the-shelf tabletop and stand-alone dispensing systems that can be integrated into existing assembly processes. Hernon® has developed this line of products to meet today’s stringent production demands that require extreme accuracy and repeatability.

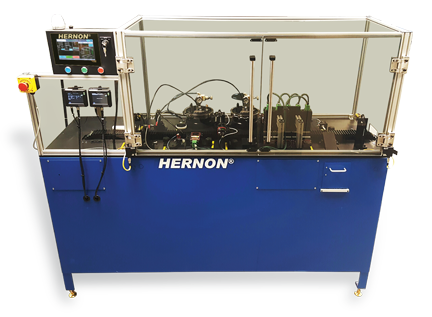

Autosealer® 5220 Benchtop Conveyor Series

- Automated ammunition sealing system

- Manual Feed, Automatic Unload

- 20 ppm Max Speed

- 380 acp Through 50 Cal

- No Tooling Change Required For Different Parts

- Footprint 24” x 30” x 12” (Benchtop Design)

Autosealer® 5200 Inline Conveyor Series

- The Autosealer® 5200 series is a unique line of cost-effective, compact, ammunition sealing systems designed for smaller production environments.

- Designed for easy integration into existing manufacturing systems

- Supports a wide variety of ammunition types and sizes

- All models are capable of sealing blank ammunition

- Seals up to 200 rounds per minute

- Utilizes Hernon’s Sureshot® 3500 microjet dispensing technology and the Ultracure® 9 UV LED curing light to precisely seal and cure each bullet

Production speeds: Contingent on the cartridge size

Autosealer® 5220: 20 ppm – Data Sheet

Autosealer® 5201: 60 ppm – Data Sheet

Autosealer® 5216: 120 ppm * Capable of sealing blank ammunition at 120 ppm – Data Sheet

Autosealer® 5226: 240 ppm * Capable of sealing blank ammunition at 120 ppm – Data Sheet

Autosealer® 5251: 60 ppm (50BMG) * Large caliber ammunition sealing system: .50 caliber and up.

Autosealer® 5100

- A highly specialized shot shell primer sealing system

- Can seal multiple shot shell gauges

- Seals up to 80 shells per minute

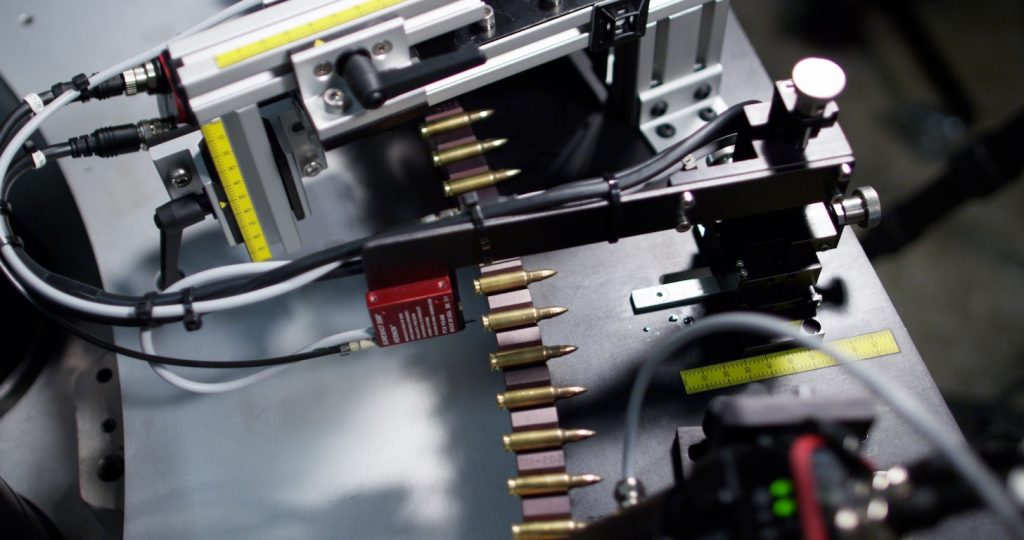

Bowl Feeding System

- Stainless steel construction

- Bowl Diameter: 24”

- Supports a variety of ammunition types and sizes

- Quick Caliber change over (Estimated 15 minutes)

- Includes conversion wheel and two diverter arms

- Production Speeds: 9mm calibers run at 200 ppm & .338 calibers run at 90 ppm.

- Includes “Zig-Zag” magazine for precision part placement (see image below)

- Capable of sealing calibers up to and including 50 cal.

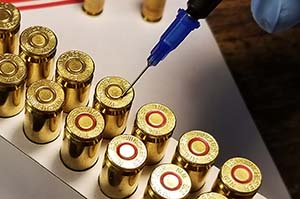

Accurizer – Manual Sealing Kit

- For craft manufacturers and reloaders

- Protect ammunition against water and other contaminants

- Seal store-bought or re-loaded ammunition

- Ammunition ready for use the next day

- Seal various calibers and types

- Learn more at www.accurizer.com